Abstract

Stoichiometric hydroxyapatite (Ca10(PO)6(OH)2, HAP) foams have been produced. The porous parts were prepared from a calcined HAP powder and egg white as a bio and non-toxic pore promoter. The colloidal slurry was prepared, poured into cylindrical molds, dried, unmolded, and sintered at 1200 °C. The effects of the concentration of the solid loading, of the dispersing agent, and the foaming agent on the ceramic preparation were examined. X-ray diffraction (XRD) and Fourier transform infrared (FTIR) were used to evaluate the composition and the structure of the sintered HAP ceramics. Scanning electron microscopy (SEM) was used for microstructural analysis. The XRD analysis of the porous parts, prepared under optimized conditions, showed the presence of crystallized HAP (JCPDS 9-432) as a single phase. SEM images showed existence of open and interconnected micro and macropores in the ceramics. The use of the egg white protein as pore former provides a total porosity of 86 vol% and a foam-structure that allows to a microporous wall.

The proposed foaming mechanism

Similar content being viewed by others

References

Scheffler, M., Colombo, P.: Cellular ceramics: structure, manufacturing, properties and applications. (2006). https://doi.org/10.1002/3527606696

Gauckler, L.J., Waeber, M.M., Conti, C., Jacob-Duliere, M.: Ceramic foam for molten metal filtration. JOM. 37, 47–50 (1985). https://doi.org/10.1007/BF03258640

Cunningham, E., Dunne, N., Walker, G., Maggs, C., Wilcox, R., Buchanan, F.: Hydroxyapatite bone substitutes developed via replication of natural marine sponges. J Mater Sci Mater Med. 21, 2255–2261 (2009). https://doi.org/10.1007/s10856-009-3961-4

Dutta Roy, T., Simon, J.L., Ricci, J.L., Rekow, E.D., Thompson, V.P., Parsons, J.R.: Performance of hydroxyapatite bone repair scaffolds created via three-dimensional fabrication techniques. J Biomed Mater Res A. 67, 1228–1237 (2003). https://doi.org/10.1002/jbm.a.20034

Mueller, B., Treccani, L., Rezwan, K.: Antibacterial active open-porous hydroxyapatite/lysozyme scaffolds suitable as bone graft and depot for localised drug delivery. J Biomater Appl. 31, 0885328216688074 (2017). https://doi.org/10.1177/0885328216688074

Innocentini, M.D.D.M., Rasteira, V.D., Potoczek, M., Chmielarz, A., Kocyło, E.: Physical, fluid dynamic and mechanical properties of alumina gel-cast foams manufactured using agarose or ovalbumin as gelling agents. J Mater Res. 32, 2810–2818 (2017). https://doi.org/10.1557/jmr.2017.263

Biswas, P., Varaprasad, K., Ramavath, P., Suresh, M.B., Khanra, A.K., Johnson, R.: Development of cordierite based reticulated foams with improved mechanical properties for porous burner applications. Trans Indian Ceram Soc. 76, 56–61 (2017). https://doi.org/10.1080/0371750X.2016.1232178

Dionigi, C., Liotta, L.F., Ortolani, L., Pantaleo, G., Ivanovska, T., Ruani, G.: New active meso-porous titania foam as size limiter for metal nanoparticles. J Alloys Compd. 735, 1611–1619 (2018). https://doi.org/10.1016/j.jallcom.2017.11.305

Arami-Niya, A., Rufford, T.E., Zhu, Z.: Activated carbon monoliths with hierarchical pore structure from tar pitch and coal powder for the adsorption of CO2, CH4and N2. Carbon. 103, 115–124 (2016). https://doi.org/10.1016/j.carbon.2016.02.098

Meskinfam, M., Bertoldi, S., Albanese, N., Cerri, A., Tanzi, M.C., Imani, R., Baheiraei, N., Farokhi, M., Farè, S.: Polyurethane foam/nano hydroxyapatite composite as a suitable scaffold for bone tissue regeneration. Mater Sci Eng C. 82, 130–140 (2018). https://doi.org/10.1016/j.msec.2017.08.064

de Groot, K.: Bioceramics consisting of calcium phosphate salts. Biomaterials. 1, 47–50 (1980). https://doi.org/10.1016/0142-9612(80)90059-9

Hench, L.L.: Third-generation biomedical materials. Science. 295, 1014–1017 (2002). https://doi.org/10.1126/science.1067404

Kantharia, N., Naik, S., Apte, S., Kheur, M., Kheur, S., Kale, B.: Nano-hydroxyapatite and its contemporary applications. Bone. 34, 1–71 (2014) http://www.iadrsd.org/wp-content/journal/JDRSD_15_13R6.pdf

Oliveira, M., Mansur, H.S.: Synthetic tooth enamel: SEM characterization of a fluoride hydroxyapatite coating for dentistry applications. Mater Res. 10, 115–118 (2007) http://www.scielo.br/scielo.php?script=sci_arttext&pid=S1516-14392007000200004&nrm=iso

Chevalier, E., Chulia, D., Pouget, C., Viana, M.: Fabrication of porous substrates: a review of processes using pore forming agents in the biomaterial field. J Pharm Sci. 97, 1135–1154 (2008). https://doi.org/10.1002/jps.21059

Castilho, M., Moseke, C., Ewald, A., Gbureck, U., Groll, J., Pires, I., Teßmar, J., Vorndran, E.: Direct 3D powder printing of biphasic calcium phosphate scaffolds for substitution of complex bone defects. Biofabrication. 6, 015006 (2014). https://doi.org/10.1088/1758-5082/6/1/015006

Tancret, F., Bouler, J.M., Chamousset, J., Minois, L.M.: Modelling the mechanical properties of microporous and macroporous biphasic calcium phosphate bioceramics. J Eur Ceram Soc. 26, 3647–3656 (2006). https://doi.org/10.1016/j.jeurceramsoc.2005.12.015

Wang, C., Kasuga, T., Nogami, M.: Macroporous calcium phosphate glass-ceramic prepared by two-step pressing technique and using sucrose as a pore former. J Mater Sci Mater Med. 16, 739–744 (2005). https://doi.org/10.1007/s10856-005-2611-8

Lee, D.S.H., Pai, Y., Chang, S., Kim, D.H.: Microstructure, physical properties, and bone regeneration effect of the nano-sized β-tricalcium phosphate granules. Mater Sci Eng C. 58, 971–976 (2016). https://doi.org/10.1016/j.msec.2015.09.047

Hatim, Z., Michrafy, A., Elassfouri, M., Abida, F.: Stoichiometry and particle morphology effects on the aptitude to compaction of apatitic structure powders. Powder Technol. 190, 210–214 (2009). https://doi.org/10.1016/j.powtec.2008.04.040

Pontier, C., Viana, M., Champion, E., Bernache-Assollant, D., Chulia, D.: About the use of stoichiometric hydroxyapatite in compression—incidence of manufacturing process on compressibility. Eur J Pharm Biopharm. 51, 249–257 (2001). https://doi.org/10.1016/S0939-6411(01)00137-0

Gervaso, F., Padmanabhan, S.K., Scalera, F., Sannino, A., Licciulli, A.: Mechanical stability of highly porous hydroxyapatite scaffolds during different stages of in vitro studies. Mater Lett. 185, 239–242 (2016). https://doi.org/10.1016/j.matlet.2016.08.139

Ramay, H.R., Zhang, M.: Preparation of porous hydroxyapatite scaffolds by combination of the gel-casting and polymer sponge methods. Biomaterials. 24, 3293–3302 (2003). https://doi.org/10.1016/S0142-9612(03)00171-6

Poorvisha, R., Suriyaraj, S.P., Thavamani, P., Naidu, R., Megharaj, M., Bhattacharyya, A., Selvakumar, R.: Synthesis and characterisation of 3-dimensional hydroxyapatite nanostructures using a thermoplastic polyurethane nanofiber sacrificial template. RSC Adv. 5, 97773–97780 (2015). https://doi.org/10.1039/C5RA18593A

Farrokhi-Rad, M., Loghmani, S.K., Shahrabi, T., Khanmohammadi, S.: Electrophoretic deposition of hydroxyapatite nanostructured coatings with controlled porosity. J Eur Ceram Soc. 34, 97–106 (2014). https://doi.org/10.1016/j.jeurceramsoc.2013.07.022

Woottichaiwat, S., Puajindanetr, S., Best, S.M.: Fabrication of porous hydroxyapatite through combination of sacrificial template and direct foaming techniques. Eng J. 15, 1–15 (2011). https://doi.org/10.4186/ej.2011.15.2.1

Potoczek, M.: Hydroxyapatite foams produced by gelcasting using agarose. Mater Lett. 62, 1055–1057 (2008). https://doi.org/10.1016/j.matlet.2007.07.043

Naqshbandi, A., Sopyan, I.: Gunawan, development of porous calcium phosphate bioceramics for bone implant applications: a review. Recent Patents Mater Sci. 6, 238–252 (2013). https://doi.org/10.2174/18744648113069990012

Lemos, A.F., Ferreira, J.M.F.: Combining foaming and starch consolidation methods to develop macroporous hydroxyapatite implants. Key Eng Mater. 254-256, 1041–1044 (2004). https://doi.org/10.4028/www.scientific.net/KEM.254-256.1041

Macchetta, A., Turner, I.G., Bowen, C.R.: Fabrication of HA/TCP scaffolds with a graded and porous structure using a camphene-based freeze-casting method. Acta Biomater. 5, 1319–1327 (2009). https://doi.org/10.1016/j.actbio.2008.11.009

Hesaraki, S., Zamanian, A., Hafezi, M.: Montmorillonite-added calcium phosphate bioceramic foams. Key Eng Mater. 361-363, 111–114 (2008). https://doi.org/10.4028/www.scientific.net/KEM.361-363.111

Rust, A.C., Manga, M.: Effects of bubble deformation on the viscosity of dilute suspensions. J Non-NewtonIAN Fluid Mech. 104, 53–63 (2002). https://doi.org/10.1016/S0377-0257(02)00013-7

Liu, Y.-F., Oey, I., Bremer, P., Carne, A., Silcock, P.: Effects of pH, temperature and pulsed electric fields on the turbidity and protein aggregation of ovomucin-depleted egg white. Food Res Int. 91, 161–170 (2017). https://doi.org/10.1016/j.foodres.2016.12.005

Studart, A.R., Gonzenbach, U.T., Tervoort, E., Gauckler, L.J.: Processing routes to macroporous ceramics: a review. J Am Ceram Soc. 89, 1771–1789 (2006). https://doi.org/10.1111/j.1551-2916.2006.01044.x

Liu, J., Miao, X.: Porous alumina ceramics prepared by slurry infiltration of expanded polystyrene beads. J Mater Sci. 40, 6145–6150 (2005). https://doi.org/10.1007/s10853-005-3165-3

Montufar, E.B., Traykova, T., Schacht, E., Ambrosio, L., Santin, M., Planell, J.A., Ginebra, M.-P.: Self-hardening calcium deficient hydroxyapatite/gelatine foams for bone regeneration. J Mater Sci Mater Med. 21, 863–869 (2010). https://doi.org/10.1007/s10856-009-3918-7

Author information

Authors and Affiliations

Corresponding author

Additional information

Highlights

• A highly porous hydroxyapatite ceramics have been produced using eggs white with described pore formation process.

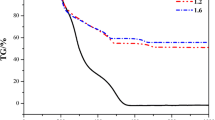

• The foam stability, the effect of the concentration of solid loading and foaming agent, has been studied.

• The interconnected macropores have a spherical shape and the ceramic walls were markedly porous.

Rights and permissions

About this article

Cite this article

Khallok, H., Ojala, S., Ezzahmouly, M. et al. Porous foams based hydroxyapatite prepared by direct foaming method using egg white as a pore promoter. J Aust Ceram Soc 55, 611–619 (2019). https://doi.org/10.1007/s41779-018-0269-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-018-0269-1